The Benefits of Migrating Legacy Systems

If you’re considering migrating legacy control systems, you’re not alone. ARC Advisory Group estimates that there are $65 billion of legacy process control systems already outdated or near the end of their lifecycle. Each manufacturer using one of those control systems has to face a reckoning, probably sooner rather than later. If production is to continue at a profitable pace, a legacy migration is inevitable. Read on to learn the benefits of migrating legacy systems now.

Why Update Industrial Control Systems?

Eventually, all industrial control systems need to be replaced. Vendors introduce new, improved systems and stop supporting the older versions; software is no longer updated. You might think your crack maintenance staff can keep your old control systems up and running, but problems will begin to emerge.

Manufacturers that rely too long on legacy control systems find they face:

- More frequent production breakdowns

- Lost productivity

- Lower quality

- A lack of replacement parts

The scramble to find appropriate parts often leads to further production delays and additional lost productivity. Furthermore, documentation can be lost or misplaced, hampering repair efforts. These issues are compounded by the fact that many of the team members most familiar with legacy control systems have retired, with even more on the way out. The loss of institutional knowledge is irretrievable.

Outdated software presents another significant problem. If software is no longer updated, that means it’s no longer receiving security patches, leaving your system vulnerable to attack.

Frequently Asked Questions About Legacy Migrations With South Shore Controls

What Legacy Control Systems Is South Shore Familiar With?

We have experience with the full range of legacy control systems, including:

- Bailey Net 90 and Infi 90

- GE 90-30 and 90-70

- Modicon 484 and 984

- Moore APACs

- Rockwell Automation 1774, PLC-2, PLC-3, PLC-5 and SLC

- Siemens S5

Which Modern Control System Does South Shore Recommend?

We take a vendor-agnostic approach to legacy migrations and recommend the control system that’s best for your operation. We have extensive expertise with control systems like:

- Emerson DeltaV

- Rockwell Automation ControlLogix

- Siemens SIMATIC S7-300, S7-400, S7-1200 and S7-1500

What Regions Can South Shore Serve?

Based in Mentor, Ohio, we work with companies in Indiana, Michigan, Ohio and Pennsylvania.

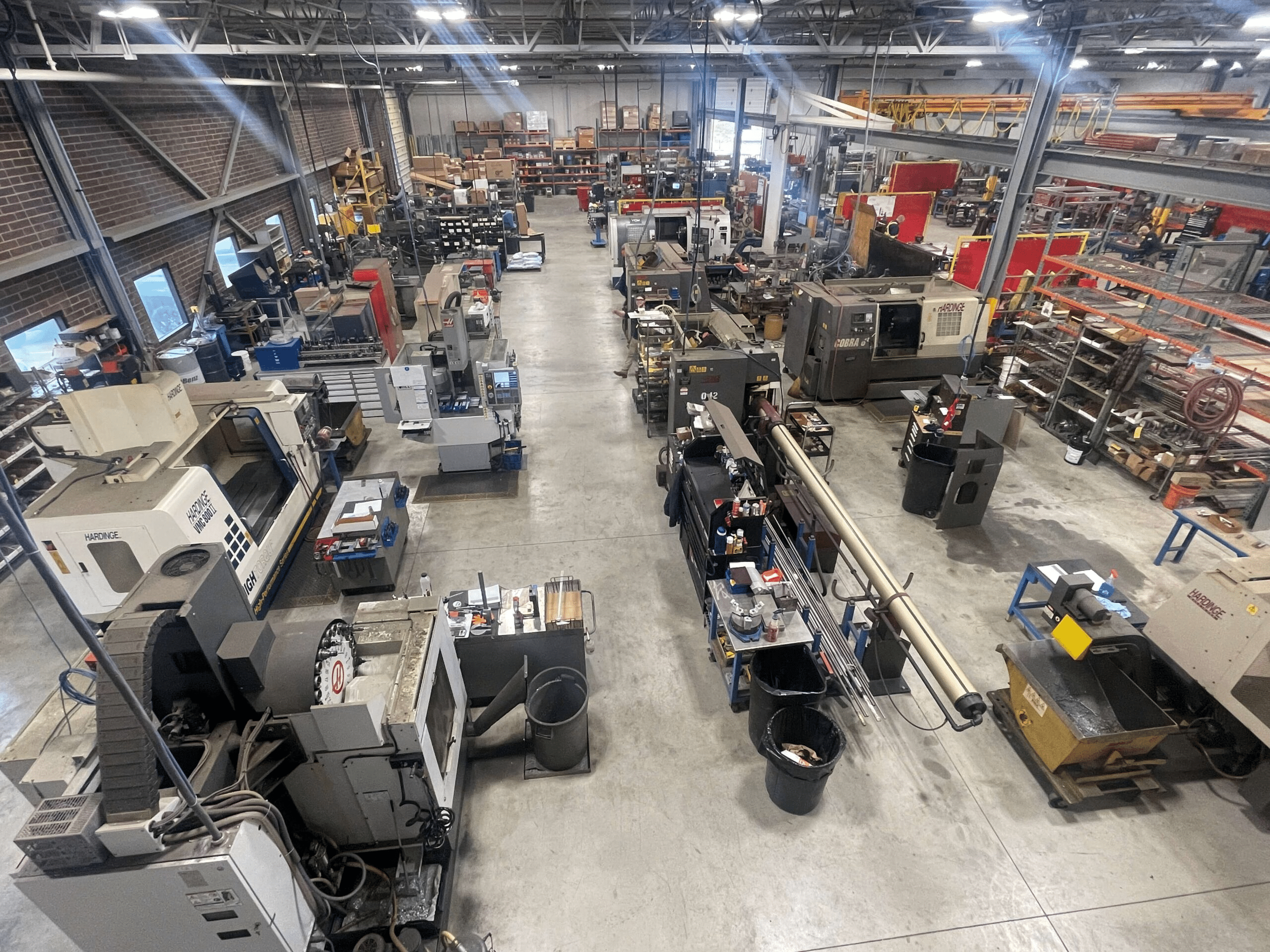

Integrated Control Systems to Meet Your Requirements

At South Shore Controls, we believe in collaborating with you to create the best integrated control system for your operation. Our turnkey approach means you receive a complete set of SolidWorks drawings, CAD drawings and operator’s manuals to ensure you get the most out of your legacy migration.

We provide systems integration and industrial automation controls that deliver tried-and-true results for our customers. Our solutions include:

- Chemical batching

- Palletizing, stacking, packing and tray handling

- Parts feeding and orienting

- Robotic/pick and place cells

- Washing and drying

- Vision inspection

Trust Your Legacy Migration Needs to South Shore Controls

South Shore Controls is the experienced partner you need when migrating legacy systems. Our legacy migration solutions minimize downtime and risk while delivering a tangible business value proposition that will have a real economic impact on your business. Contact us today to learn how we can help improve your operations.