Welding Automation

South Shore Controls Stands Out for Contract Manufacturing & Welding Services

- Skilled Welding Professionals: South Shore Controls employs a team of skilled welding professionals with extensive experience in various welding techniques. The personnel possess expertise in working with diverse materials, ensuring the ability to meet specific welding requirements.

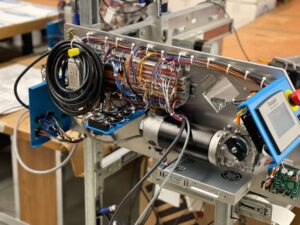

- Advanced Welding Technology: The welding facilities at South Shore Controls are equipped with state-of-the-art welding technology, ensuring precision and efficiency in welding operations. Access to advanced equipment enhances the quality and durability of welded components.

- Quality Welded Assemblies: Leveraging specialized knowledge and advanced technology results in the production of high-quality welded assemblies with structural integrity. Adherence to industry standards and best practices ensures the reliability of welded components.

- Cost-Effectiveness: Outsourcing welding operations to South Shore Controls allows manufacturers to benefit from cost efficiencies achieved by specialized welding services. Elimination of the need for in-house welding capabilities reduces overhead costs and increases overall cost-effectiveness.

- Efficiency and Timely Delivery: South Shore Controls prioritizes efficiency in welding processes, offering streamlined and optimized operations. Advanced welding techniques and efficient workflows ensure timely delivery of welded components without compromising quality.

- Focus on Core Competencies: Outsourcing welding operations enables manufacturers to focus on their core competencies, redirecting resources to strategic areas. This approach leads to increased productivity and improved overall business performance.

- Quality Assurance and Compliance: South Shore Controls maintains rigorous quality assurance measures to ensure welded components meet industry standards and specifications. Compliance with welding codes and regulations is a priority, providing manufacturers with confidence in the integrity of the welded products.

- Strategic Partnership: The collaboration with South Shore Controls establishes a strategic partnership, allowing manufacturers to leverage welding expertise, technology, and cost-effectiveness. Manufacturers can enhance their competitiveness and achieve operational excellence by outsourcing welding operations to specialized service providers.

Companies throughout Indiana, Michigan, Pennsylvania and Ohio trust South Shore Controls’ industry-leading automation system integrations. Contact us today to see what we can do for your operation.

South Shore Controls Has Your Automation Systems Solution

As a manufacturing system integrator, we have extensive experience designing, manufacturing and upgrading plant floor operations with integrated process control systems that improve production efficiency, safety and return on investment. We collaborate closely with your team to ensure your requirements are met.

You get the full benefit of our industrial automation systems expertise in a package tailored specifically to your needs. We review your system end-to-end and provide recommendations that provide the best value for your requirements.

Our highly-trained team of experts has all the tools needed to perform your automation system integration:

- Complete design, fabrication, electrical, mechanical and software integration capabilities in-house

- Project Review & Recommendations

- Electrical & Mechanical Engineering Design

- Complete Turnkey Manufacturing Services

- Control System Integration

- Software Development

- On-Site Installation Services

- Field Service & Support

Project Gallery

Automation System Integrations You Can Trust

Our years of experience mean you get the automation systems integration that meets your needs, complete with custom-developed code and software. South Shore Controls employs an integrated approach that simplifies the process for you yet delivers the high quality and return on investment that you require.

Our automation system integrations help you lower costs, boost productivity, enhance workflow efficiencies and improve product quality. We can help you gain greater flexibility to meet the needs of modern manufacturing. From design to installation and training, we handle every facet of your project. Contact us to learn more.

Automation System Integration Capabilities Include These Areas of Expertise:

- Control Panels

- Batch Process Controls

- PLC Programming

- HMI Programming

- Drive Systems

- Control System Retrofits

- Specialized Machinery

- Pick & Place Robotic Systems

- Conveying/Material Handling

- AC and DC Drives & Motion Control Upgrades

- Position & Presence Monitoring

- Temperature Sensing and Control Systems

- Available in 3 models: SM, MD, LG

- Axis options: X, X & Z, X & Z with control

Frequently Asked Questions

What is system integration?

System integration is the process of introducing automated systems to help improve the functionality of your overall operation. Examples of automation system integrations include adding robotic pick and place systems or implementing position and presence monitoring.

What is the system integrator’s role in automation?

At South Shore Controls, the industrial automation systems integrator’s role is to provide a one-stop-shopping approach to your project, delivering the design, manufacturing and installation of your automation system integration.

What are system integration challenges?

Challenges to a successful automation system integration include:

- Sourcing the right components

- Developing the correct technology interfaces

- Creating control and field instrumentation documentation

- Planning for future expansion

What is a legacy system integration?

In a legacy system integration, South Shore Controls incorporates new, modern systems to upgrade or replace equipment that is obsolete or near the end of its lifecycle.

Discuss Your Project with Our Team Today

Contact our automation and controls experts to learn how we can help improve and automate your manufacturing processes.