Turnkey Solutions

When your manufacturing processes require seamless integration and flawless execution, South Shore Controls is your trusted partner for turnkey solutions. Our services are tailored to meet the diverse needs of modern industrial operations, offering customized automation solutions that boost efficiency and productivity.

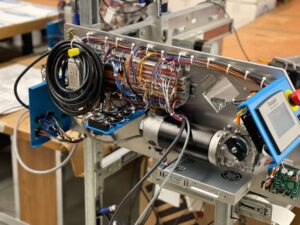

We specialize in managing automated projects, from design and engineering to installation and ongoing support. Our team delivers high-quality control panels, advanced batch process controls, and innovative robotic systems, covering all aspects of your automation needs.

For PLC programming, HMI interfaces, or drive systems, rely on South Shore Controls.

Companies throughout Indiana, Michigan, Pennsylvania and Ohio trust South Shore Controls’ industry-leading automation system integrations. Contact us today to see what we can do for your operation.

Comprehensive Turnkey Solutions from South Shore Controls

At South Shore Controls, we offer comprehensive turnkey solutions to streamline your industrial automation processes. Our expertise covers a wide range of applications, ensuring your systems operate with optimal efficiency and reliability.

Whether you need advanced control panels, precise batch process controls, or cutting-edge robotic systems, we provide tailored solutions for your specific needs. Explore our services designed to enhance productivity, improve safety, and reduce downtime.

Our turnkey solutions include:

Why Our Turnkey Solutions Are Valuable

Our industrial turnkey solutions come with a range of features.

- Comprehensive Management: We oversee the entire project from planning to implementation. Our team is dedicated to providing a hassle-free experience for our clients, ensuring that every detail is accounted for.

- Scalable Solutions: Our turnkey solutions can be adjusted to fit your business’s changing needs. This flexibility allows your business to grow and adapt without the need for significant additional investments.

- Efficient Delivery: We are committed to delivering projects on time and within budget. Our focus on efficiency helps to minimize downtime and disruption to your operations, keeping your business running smoothly.

- Expert Support: Our team of professionals is always available to offer guidance and support throughout your project. From troubleshooting issues to providing ongoing maintenance, we are here to help. Our expertise ensures that your systems continue to operate at peak performance, giving you peace of mind.

Choosing a turnkey automation solution simplifies the complex process of implementing automation systems by consolidating expertise and responsibilities.

South Shore Controls, as a trusted partner, offers manufacturers a seamless and efficient journey from conceptualization to ongoing support. Our value lies in the assurance of a comprehensive, integrated, and reliable solution delivered through a single, accountable source.

Project Gallery

South Shore Controls

Discover why South Shore Controls is your top choice for industrial turnkey solutions services.

Get Started with Turnkey Solutions From South Shore Controls

Ready to streamline your projects with expert turnkey solutions? Contact South Shore Controls today to discuss your specific needs and learn how our tailored services can benefit you. Our team is dedicated to delivering high-quality, efficient, and effective solutions across various industries.

Don’t wait – take the first step towards optimized project management with South Shore Controls. Reach out now and experience the difference that a trusted partner can make for your operations.

Frequently Asked Questions About Turnkey Solutions

Understanding turnkey solutions can help you make informed decisions for your business. Here are some common questions and answers to provide clarity.

What Are the Benefits of Turnkey Solutions?

Turnkey solutions offer comprehensive project management from start to finish, ensuring seamless integration and execution. This approach saves time and reduces stress, as one provider coordinates all aspects of the project. It guarantees consistency and reliability throughout the process, providing peace of mind.

How Do Turnkey Solutions Differ From Traditional Project Management?

Traditional project management often involves coordinating multiple vendors and stages, which can lead to delays and communication issues. Our turnkey solutions, on the other hand, are managed by us. We streamline the process and ensure a cohesive approach from beginning to end. This unified management reduces potential bottlenecks and enhances overall efficiency.

Can Turnkey Solutions Be Customized?

Yes, turnkey solutions can be tailored to meet your business’s specific needs. Providers like South Shore Controls offer scalable solutions that can adapt to your requirements. This flexibility ensures that you receive personalized services that align with your exact specifications.

Why Choose South Shore Controls for Turnkey Solutions?

South Shore Controls stands out due to its commitment to quality, innovation, and customer satisfaction. Our experienced team delivers efficient and reliable turnkey solutions, tackling complex projects with ease. We prioritize client needs, offering ongoing support and personalized attention throughout the project lifecycle, ensuring a successful outcome.