Converting Equipment for Industrial Laminating & Coating

Converting Equipment

South Shore Controls specializes in converting equipment design and manufacturing providing a range of services tailored to the needs of industries involved in processes like film and paper conversion. Here are some general capabilities:

- Winders and Unwinders:

- Design and manufacture of precision winding and unwinding equipment.

- Integration of tension control systems for consistent winding and unwinding.

- Automation features for efficient and reliable operation.

- Laminators:

- Development of laminating equipment for combining multiple layers of materials.

- Adhesive application and drying systems for effective lamination.

- Control systems to ensure precise temperature, pressure, and speed during the lamination process.

- Filter Lines:

- Design and production of filter manufacturing lines.

- Automation of processes for filter assembly, sealing, and quality control.

- Integration of testing and inspection systems to ensure filter quality.

- Experience and Expertise:

- Knowledge of industry-specific requirements and standards.

- Customization capabilities to meet unique client specifications.

- In-house testing and quality assurance processes.

Custom Winder Industrial Laminating Machines

Developed for a company that specializes in cutting-edge technology. Using specialty engineered polymers for the replacement of glass lenses. The material is layers of specialized polymer film only a few molecules thick stacked, shaped then baked together. The materials technical name is Gradient Refractive Index (GRIN) Optics.

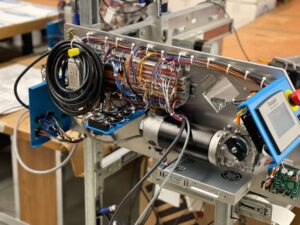

South Shore Controls developed an extremely specialized winder for this converting application.

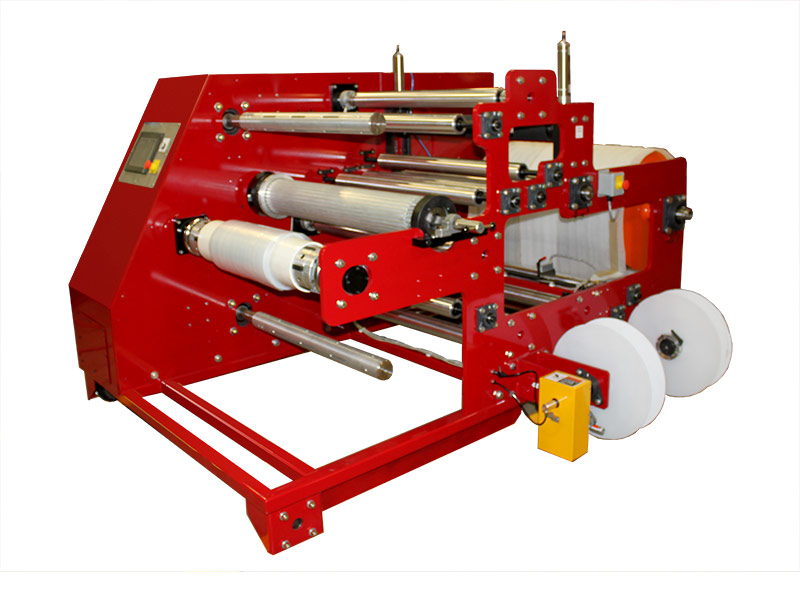

Custom Industrial Laminator

Designed and built specifically for prototyping and testing of small-scale short runs, the new industrial laminating machine is perfect for testing products. The industrial laminator will typically run 5,000 ft/day across a 7” web width, making it ideal for niche markets.

Resin Bonded Filter Line

Major filter manufacturers contacted South Shore Controls to design, engineer, build and install a new fully automated 70” line to produce resin-bonded cartridge filters.

- Fiber Unwinder

- Spiral Winder

- Heated Splicer Station

- Spiral Material Unwind

- Two-Sided Coating Station

- Finished Mandrel

- Precure Dryer

- Transfer & Conveyance System

- Matte Winder

Project Gallery

Discuss Your Project with Our Team Today

Contact our automation and controls experts to learn how we can help improve and automate your manufacturing processes.