Programming & HMI Development

South Shore Controls stands at the forefront of turnkey automation solutions, boasting exceptional software development capabilities that encompass a high level of proficiency and expertise across all major PLC brands and platforms. Our skilled team is comfortable navigating the intricacies of diverse PLC systems, including but not limited to Allen Bradley, Siemens, ABB, Trio, and more.

This versatility ensures that South Shore Controls can seamlessly integrate automation systems, regardless of the existing infrastructure, providing manufacturers with a tailored and interoperable solution.

Why Turnkey Solutions are Valuable

1. Comprehensive Expertise:

- Turnkey solutions consolidate expertise under one roof. South Shore Controls, with its skilled team, covers mechanical designs, electrical designs, software development, manufacturing, and field services. This eliminates the need for coordinating multiple vendors and ensures that every aspect is seamlessly integrated.

2. Single Point of Contact:

- Dealing with one provider simplifies communication and project management. South Shore Controls acts as a single point of contact, fostering efficient collaboration and reducing the complexities associated with coordinating multiple vendors.

3. Cohesive Integration:

- Turnkey solutions ensure that all components, from mechanical structures to software interfaces, work together seamlessly. South Shore Controls’ holistic approach guarantees a cohesive integration of automation systems, minimizing the risk of compatibility issues and optimizing overall system performance.

4. Time and Cost Efficiency:

- Dealing with multiple vendors can lead to delays and increased costs. South Shore Controls streamlines the process, reducing the time required for coordination and minimizing expenses associated with managing multiple contracts.

5. Accountability and Responsibility:

- With a turnkey solution, there is a clear point of accountability. South Shore Controls takes responsibility for the entire project, ensuring that every phase, from design to implementation and ongoing support, is executed with precision and commitment.

6. Customization and Flexibility:

- Turnkey solutions offer the flexibility to customize every aspect of the automation system according to specific requirements. South Shore Controls’ expertise allows for tailored solutions that align precisely with the unique needs of each manufacturing environment.

7. Ongoing Support and Maintenance:

- Beyond the initial implementation, South Shore Controls provides ongoing support and maintenance services. This continuity ensures that manufacturers have a reliable partner for the entire lifecycle of their automation systems, minimizing disruptions and optimizing long-term reliability.

Choosing a turnkey automation solution simplifies the complex process of implementing automation systems by consolidating expertise and responsibilities.

South Shore Controls, as a trusted partner, offers manufacturers a seamless and efficient journey, from conceptualization to ongoing support. The value lies in the assurance of a comprehensive, integrated, and reliable solution, all delivered through a single, accountable source.

The integration capabilities extend beyond just PLCs, covering a spectrum of automation technologies. South Shore Controls excels in harmonizing various components, from HMI interfaces to sophisticated software applications, ensuring a cohesive and efficient automation ecosystem. This holistic integration approach contributes to streamlined operations and optimized performance.

South Shore Controls offers both remote and on-site services, providing manufacturers with flexibility and convenience. The remote services enable swift troubleshooting and support, addressing issues efficiently without the need for on-site presence. In instances where physical intervention is required, the company’s on-site services ensure a hands-on approach to resolve complexities, minimizing downtime and maintaining the seamless operation of automation systems.

In essence, South Shore Controls’ software development capabilities for turnkey automation solutions are a testament to their adaptability and excellence. The comfortability and expertise across major PLC brands, coupled with comprehensive integration capabilities and flexible service options, position South Shore Controls as a trusted partner for manufacturers seeking a sophisticated, tailored, and reliable automation solution.

The Importance of Programming

Automation controls programming services and Human Machine Interface (HMI) programming are pivotal elements in any new automation project, playing a crucial role in defining the functionality, efficiency, and user experience of the entire system.

Automation Controls Programming:

- Functionality and Precision: Automation controls programming determines how the equipment and machinery behave. It ensures precise and reliable execution of tasks, contributing to the overall functionality of the automation system.

- Optimization and Efficiency: Well-crafted programming maximizes the efficiency of the entire process. It allows for streamlined workflows, reduced cycle times, and optimal resource utilization, ultimately enhancing productivity.

- Customization and Adaptability: Automation controls programming enables customization to meet specific manufacturing requirements. The flexibility to adapt and modify programming ensures that the automation system aligns precisely with the unique needs of the project.

HMI Programming:

- User Interface and Experience: The HMI serves as the interface between operators and the automation system. Effective HMI programming ensures an intuitive and user-friendly interface, enhancing operator experience and reducing the learning curve for new users.

- Real-time Monitoring and Control: HMI programming enables real-time monitoring of processes and provides control capabilities. This visibility empowers operators to make informed decisions, respond to changes promptly, and optimize system performance.

- Data Analysis and Reporting: HMI programming facilitates data analysis and reporting functionalities. Operators can access key metrics, trends, and performance indicators, supporting data-driven decision-making and enhancing overall efficiency.

Why South Shore Controls?

South Shore Controls as a Trusted Vendor:

- Expertise Across Platforms: South Shore Controls possesses expertise across major PLC brands and platforms, ensuring proficiency in automation controls programming for a wide range of systems.

- Tailored Solutions: The company provides customized automation controls and HMI programming, tailoring solutions to the specific needs of each project. This approach ensures that the programming aligns precisely with the project’s goals and requirements.

- Proven Track Record: South Shore Controls has a proven track record of successful automation projects, earning the trust of clients through reliable and efficient programming services.

- Comprehensive Support: Beyond programming, South Shore Controls offers comprehensive support, including troubleshooting, maintenance, and continuous improvement services, ensuring the longevity and optimal performance of the automation systems.

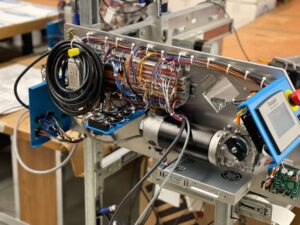

Project Gallery

Discuss Your Project with Our Team Today

Contact our automation and controls experts to learn how we can help improve and automate your manufacturing processes.