Industrial Washing Systems

Industrial Wash Systems

South Shore Controls, through the Niagara Systems brand, offers comprehensive industrial washing solutions with a focus on excellence in design, manufacturing, and service.

Niagara Systems has established a distinct niche by specializing in the design and construction of highly customized wash systems. Their expertise lies in crafting industrial washing solutions that cater to the unique and specific requirements of various industries.

Whether addressing intricate part geometries, specialized cleaning needs, or stringent industry standards, Niagara Systems excels in delivering tailored wash systems that optimize efficiency, ensure precision cleaning, and seamlessly integrate with the client’s production processes.

This commitment to customization, paired with cutting-edge technology, positions Niagara Systems as a trusted partner for those seeking tailored solutions to their industrial cleaning challenges.

Companies throughout Indiana, Michigan, Pennsylvania and Ohio trust South Shore Controls’ industry-leading automation system integrations. Contact us today to see what we can do for your operation.

Niagara Systems – More Than Washing

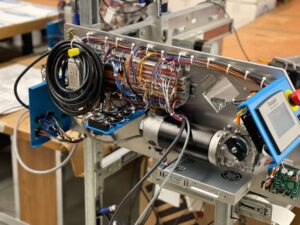

Industrial Washers: Niagara Systems, operating under the South Shore Controls brand, is a leading provider of industrial washing solutions known for their excellence in design, manufacturing, and service. Specializing in customized industrial washers, they deliver high-performance systems tailored to the unique cleaning requirements of diverse industries. Whether it involves precision cleaning of parts, components, or containers, Niagara Systems ensures thorough and consistent results through their advanced washing solutions.

Chemical Processing Solutions: Niagara Systems goes beyond traditional industrial washing by offering a comprehensive suite of chemical processing solutions. This includes expertise in various chemical applications such as etching, pickling, passivating, and more. These chemical processes are integral to achieving specific surface treatments, corrosion resistance, and material enhancements. Niagara Systems collaborates closely with clients to understand their unique needs and recommends suitable chemicals, ensuring that the chosen processes align with industry standards and environmental considerations.

- Etching: Niagara Systems provides advanced etching solutions for controlled material removal and surface modification. This process is crucial for achieving precise surface profiles and preparing materials for subsequent manufacturing steps.

- Pickling: The pickling process offered by Niagara Systems involves the removal of oxides and scales from metal surfaces, enhancing the cleanliness and integrity of the materials. This is particularly important in industries where metal surfaces need to meet stringent quality standards.

- Passivating: Niagara Systems excels in passivation, a process that enhances the corrosion resistance of stainless steel and other alloys. By removing free iron and other contaminants, passivation ensures the longevity and durability of metal components in challenging environments.

Automation Integration: Niagara Systems understands the pivotal role of automation in optimizing industrial processes. Their offerings include comprehensive automation integration solutions, not only for the washing process but also for chemical processing steps. Automated loading and unloading systems, conveyor integration, and robotic handling are seamlessly integrated upstream and downstream from the chemical processes, ensuring a cohesive and efficient workflow.

Service and Support: Committed to customer satisfaction, South Shore Controls provides extensive service and support for their chemical processing solutions. This includes ongoing maintenance, troubleshooting, and personalized support to guarantee that the chemical processing systems operate at peak performance throughout their lifecycle.

More than Washing: Niagara Systems’ chemical processing solutions encompass a range of applications, including washing etching, pickling, passivating, and more. This, combined with their expertise in custom material handling, robotics and automation integration, positions them as a trusted partner for industries with diverse and demanding cleaning and material treatment requirements. For the latest and most detailed information, direct communication with South Shore Controls is recommended.

Project Gallery

Discuss Your Project with Our Team Today

Contact our automation and controls experts to learn how we can help improve and automate your manufacturing processes.