Technology advances and evolves at an exponential rate every day. All processes are also changing fast which leads to the development of new strategies for producing products or services. Automation is not a new concept to us. We are now living in a world full of industries with robots and computers helping to perform repetitive work activities. Automated systems improve the overall company competitiveness on the market by reducing the operational cost and increasing both efficiency and productivity. Monotonous, physically demanding tasks in a hazardous environment are recommended to be performed automatically.

South Shore Controls Industrial Automation Project

(Converting Completely Manual System for Laying Down and Cung Gasket Material into Automated System)

There are still tasks, however, that are preferred to be done manually. Tasks that are too difficult to be automated and with a short life cycle is recommended to be accomplished by humans. In addition, manual work is favored when manufacturing customized or brand-new products.

Now that you know the advantages and limits of automated systems, you should also carefully look at several factors that should be considered when one decides to shift to automated systems. These considerations can guide you to ensure that your automated systems will be effective. Read on and take your first step to create a successful automation project!

1. Establish your automation vision.

For your automation project to be successful, you should start with a purposeful vision. Your vision must be aligned to the needs of your organization, and these may include improving productivity, process efficiency, data quality, product quality, etc. In defining your vision, the key stakeholders need to be involved. However, it is the IT team that still needs to govern the project.

Assess the opportunities and risks associated with the project. Will shifting to an automated system help your company advance on the market? Will you lose more if you chose not to incorporate automation technologies in your process? Consider these risks and decide whether to continue or not the project.

2. Practice good communication among stakeholders.

Believe it or not, good communication is always the key to a successful project. At the beginning of an automation project, concerned stakeholders should provide their objectives in mind so that these will be all accounted for. For instance, the production group wants increased productivity and zero downtime, the quality group wants products conforming to standards, and the IT team wants a sustainable system. If these are not addressed at the early phase of the project, your automated system may not meet as many requirements as possible thereby making it less efficient than it should be.

3. Identify the best processes that need automation.

To help define the best processes that need to be automated, consider the following questions:

- Will this process generate the fastest benefits if we convert it into an automated system?

- Does the manual process need an upgrade or improvement? Will the benefits be greater than the added cost and effort?

As previously discussed, some tasks that are better left and done by humans. Equipment maintenance, programming and software upgrades, project developments, and planning the factory layout are areas that will always be regarded as a human’s area. Tasks, which are prone to human errors and are repetitive, require an automated system.

4. Create a multi-disciplinary team.

A successful automation project does not just end at its installation. The maintenance and sustainability of the system are also of utmost importance. Staff should be trained to develop automation-related skills that are essential for maintaining the system. Your IT team should be present at the earliest stage of the project, so they can be able to acquire the best practices and knowledge of the new system. With this, IT can be tasked to train operating personnel and provide technical support whenever necessary. Your organization should prepare a team with integration and programming capabilities, and technicians to keep the systems running. With this, you can also refrain from contacting your third-party service provider, from time to time, to assist you.

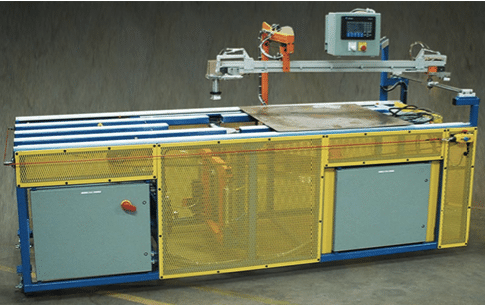

South Shore Controls System Integraon Project

(Added a Vision Monitoring System in a Standard Powdered Roller Conveyor)

5. Choose the appropriate automation tool.

There is a wide range of automation tools on the market today. You should select the simplest, most flexible and usable among the existing choices. Selecting an automation tool that is unnecessarily complex and does not meet your requirements hinders the success of your automation project.

Conclusion:

Succeeding in your automation project is not hard at all. The main key is to take all considerations into account at the earliest possible, so you have more time to do the necessary changes in your project if in case you need to.

What We Do

South Shore Controls core expertise is designing and implementing sophisticated control systems for manufacturing process lines and other industrial applications. Using highly skilled Controls Engineers, Electrical Engineers, Mechanical Engineers and, Information Technology experts we integrate plant equipment to automate manufacturing processes from plant floor to the enterprise level.

Automation

- Gain capacity

- Expand product offerings

- Improve efficiencies

- Minimize waste

- Enable predicative maintenance

- Improve quality

Download Our Updated Automation & Controls Brochure

Click the brochure image or this link to download the brochure. [924kb]

Recent Posts

- Rockwell Product Life Cycle Management & How South Shore Controls Can Help

- What Is Industrial Automation? A Guide to Industrial Automation Systems

- A Guide to Pick and Place Robots: Benefits and Applications of Pick and Place Automation

- The Different Types of Industrial Automation Systems and How They Can Benefit You

- What Is Web Converting?

South Shore Controls is headquartered in Mentor, Ohio. We are experts at designing, manufacturing, installing, and servicing automation equipment and integrated systems. Our team consists of more than 50 well-rounded and experienced professionals with diverse backgrounds and skill sets. We are always looking for quality and experienced individuals to join our growing team. We offer highly competitive wages with a comprehensive benefit package.

To submit your resume:

Email us at

careers@southshorecontrols.com

– or – Mail your resume to: South Shore Controls Attn: HR Director 9395 Pinecone Drive Mentor, OH 44060