Fabrication Services

At South Shore Controls, we deliver precision fabrication services designed to meet the exacting needs of modern industries. From custom fabrication solutions to fully integrated fabrication systems, we provide the expertise, technology, and attention to detail required to bring your projects to life. Our approach combines innovative fabrication automation with proven craftsmanship to ensure your components and assemblies exceed performance standards.

For over 30 years, we’ve partnered with manufacturers across diverse sectors, including aerospace, automotive, food and beverage, pharmaceuticals, and industrial manufacturing. Whether your project requires a single prototype or large-scale production, South Shore Controls offers reliable, scalable, and industrial fabrication services that deliver measurable results.

Our Comprehensive Fabrication Capabilities

At South Shore Controls, we offer a full range of fabrication services to support complex projects across industries. Whether you need precision components, custom assemblies, or fully integrated fabrication systems, we provide reliable solutions tailored to your operational requirements.

Precision Cutting and Forming

Our advanced cutting and forming processes ensure accuracy and consistency, even for the most intricate designs. Using state-of-the-art equipment, we can work with various materials—metals, alloys, and specialty materials—to produce components with tight tolerances and superior finishes.

Welding and Assembly

We specialize in high-quality welding and assembly services to create durable, dependable products. Our team of certified welders and engineers ensures every joint and assembly meets rigorous quality standards, whether it’s for small-scale components or large structural fabrications.

Custom Fabrication Solutions

No two projects are alike. That’s why our team excels in providing custom fabrication solutions to meet your specific challenges. From designing prototypes to full-scale production, we collaborate closely with you to deliver tailored results that align with your objectives.

Fabrication Automation

For businesses seeking to optimize production, we integrate fabrication automation into your processes. By combining our fabrication expertise with automation solutions, we reduce manual intervention, improve efficiency, and enhance consistency across your manufacturing workflows.

Industrial Fabrication Systems

We design and build industrial fabrication systems that seamlessly align with your production requirements. From standalone systems to integrated solutions, we ensure that your fabrication processes support productivity, scalability, and cost-effectiveness.

Why Choose South Shore Controls for Fabrication Solutions

We understand that precision, durability, and efficiency are critical when it comes to fabrication solutions. Our experienced team leverages cutting-edge technology and decades of expertise to deliver results that align with your exact requirements. Here’s what sets us apart:

- Advanced Technology: We utilize the latest equipment to ensure accuracy, consistency, and quality at every stage of fabrication.

- Custom Solutions: Every project is approached with a tailored plan to meet your unique specifications and performance goals.

- Scalability: From prototypes to high-volume production, our fabrication services are flexible and adaptable to your needs.

- Integration Expertise: Our capabilities extend to fabrication automation, ensuring seamless incorporation into existing systems.

- Commitment to Quality: Rigorous quality control processes ensure that every component and system meets the highest industry standards.

We don’t just fabricate components—we build solutions that support your operations, drive efficiency, and ensure long-term success.

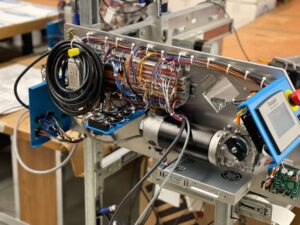

Project Gallery

South Shore Controls

Discover why South Shore Controls is your top choice for fabrication services.

FAQs About Fabrication Services

Have questions about South Shore Controls’ fabrication services? Explore our FAQs to learn more about our materials, capabilities, and how we deliver tailored solutions to meet the needs of industries like aerospace, automotive, and manufacturing.

What materials can South Shore Controls work with for fabrication?

We work with a wide range of materials, including metals, alloys, stainless steel, and specialty materials. Our versatile capabilities ensure we can meet your project’s specific requirements with precision and consistency.

Can you provide custom fabrication solutions for unique projects?

Yes, we specialize in custom fabrication solutions tailored to your exact specifications. Our team collaborates closely with you to design, prototype, and produce components or systems that solve your unique challenges.

Do you offer fabrication automation solutions?

Absolutely. Our expertise in fabrication automation allows us to integrate systems that enhance production efficiency, reduce manual processes, and improve overall workflow consistency.

What industries do you serve with your fabrication services?

We serve industries such as aerospace, automotive, food and beverage, pharmaceuticals, and industrial manufacturing. Our experience ensures we can meet the unique demands of any sector.

How does South Shore Controls ensure quality in its fabrication services?

Quality is a core focus at South Shore Controls. We follow rigorous quality control processes, including advanced inspections and testing, to ensure all components and systems meet or exceed industry standards.

Take Your Fabrication Operations to the Next Level

Discover how South Shore Controls can deliver fabrication solutions that align with your production goals and operational needs. From precision components to fully integrated fabrication systems, our team is ready to provide unmatched quality, expertise, and innovation.

Click below to explore our services and connect with an expert today. Contact South Shore Controls today