In-House Manufacturing Services

Many businesses struggle with delays, inconsistent quality, and lack of flexibility when outsourcing their manufacturing needs. These challenges can lead to higher costs and missed opportunities. In-house manufacturing solves these problems by offering control over production, from initial design to final assembly.

At South Shore Controls, we handle everything internally, from mechanical design to industrial production design, ensuring faster processes, higher customization, and superior quality control. With all operations under one roof, we deliver solutions tailored to your specific needs.

Comprehensive In-House Manufacturing Services from South Shore Controls

We provide in-house manufacturing services to industries such as aerospace, automotive, and more. We coordinate design, production, and testing to find solutions while maintaining quality control throughout the process. Our experts leverage advanced technology to provide businesses with efficient and cost-effective manufacturing solutions.

Industrial Production Design

We specialize in custom industrial production design, developing machinery and production lines tailored to your specific business requirements. Whether you’re seeking high-precision components or innovative automation systems, we create designs that enhance productivity and minimize downtime. South Shore Controls excels in mechanical design, where each project begins with a meticulous blueprint that aligns functionality, safety, and efficiency. This attention to detail guarantees that we deliver equipment that meets the highest standards across diverse industries.

Machining and Fabrication

We strive for precision and quality with our machining and fabrication services. Using advanced CNC machining techniques, we handle projects of all sizes, producing components with tight tolerances for critical applications. Forming processes like bending, rolling, and stamping are executed with accuracy, ensuring parts with specific geometries meet both functional and aesthetic needs. Our capabilities extend to metal fabrication and parts manufacturing, ensuring consistency in every order. This versatility allows us to create everything from small components to large-scale industrial systems.

Electrical and Mechanical Design

Our electrical and mechanical design services ensure seamless integration and performance optimization of all systems we develop. We work closely with clients to create automation systems that meet specific operational goals, such as enhancing productivity or reducing energy consumption. From electrical control panels to fully integrated automation systems, South Shore Controls provides end-to-end design services that streamline the process from concept to implementation, ensuring a smooth and cost-efficient outcome.

Testing and Validation

All systems undergo comprehensive testing and validation prior to deployment. At South Shore Controls, we conduct rigorous assessments to ensure that each product meets both industry standards and client specifications. This ensures that our systems are reliable, minimizing the risk of operational downtime and guaranteeing peak performance under real-world conditions.

Precision Cutting Technologies

At the forefront of our manufacturing capabilities are precision cutting technologies like laser cutting and waterjet cutting. Our laser-cutting process uses advanced technology to achieve intricate, high-precision cuts while minimizing material waste. Meanwhile, waterjet cutting provides flexibility, handling a wide range of materials such as metals, plastics, and composites. These processes allow us to meet complex design specifications while maintaining efficiency and quality throughout.

Welding and Fabrication

Welding is another core competency at South Shore Controls. We use techniques such as MIG and TIG welding to ensure the structural integrity of our assemblies. Our ability to combine materials with precision contributes to the quality of every project we undertake. Fabrication, a multifaceted process involving cutting, welding, and assembly, allows us to transform raw materials into finished products that range from small components to large, custom-built systems.

Advantages of South Shore Controls’ In-House Production Solutions

In-house production offers businesses a competitive edge by allowing full control over every step of the manufacturing process. This approach increases efficiency and ensures higher quality standards and the ability to customize solutions to meet specific client needs. With South Shore Controls, you gain access to a wide range of advanced manufacturing capabilities—all housed under one roof.

Key benefits of in-house production include:

- Quality Control. By keeping all aspects of production within South Shore Controls, we are able to monitor each phase rigorously. This ensures that every part, from initial design to final assembly, meets strict quality standards. Our in-house manufacturing design allows us to catch potential issues early, reducing costly rework and ensuring consistency across all projects.

- Faster Turnaround. With in-house production, we eliminate the delays typically associated with coordinating with external vendors. This streamlined process allows us to respond quickly to client needs, from concept to finished product, resulting in significantly shorter lead times.

- Cost-Effective. Consolidating all processes under one roof enables us to minimize overhead and pass those savings on to our clients. In addition to reduced transportation costs, the integration of design, production, and testing helps optimize resources for greater efficiency.

- Customization. Developing tailored solutions is much easier when the entire process is managed internally. We can seamlessly adjust designs or specifications to meet evolving client needs without the delays or complications that often arise with outsourcing

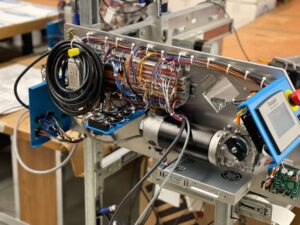

Project Gallery

South Shore Controls

Find out more about why South Shore Controls is your top choice for in-house manufacturing services.

Frequently Asked Questions About In-House Manufacturing

Understanding our in-house manufacturing services can help you make informed decisions for your business. Here are some common questions and answers to provide clarity.

Why is in-house manufacturing beneficial for custom projects?

In-house manufacturing offers complete control over every step, from industrial production design to final assembly. This control allows South Shore Controls to deliver highly customized solutions while maintaining strict quality standards throughout the process. By keeping everything internal, we also reduce lead times and can make real-time adjustments as needed.

What industries benefit most from in-house production?

Industries such as aerospace, automotive, and heavy manufacturing benefit greatly from in-house production. These sectors often require precise, custom solutions, and South Shore Controls excels in providing tailored systems that meet the stringent requirements of these fields. In-house capabilities allow for rapid prototyping and efficient production, ensuring that even complex, high-tech designs are handled smoothly.

How does South Shore Controls maintain quality in its manufacturing process?

South Shore Controls implements a thorough quality control process at each stage of production. From machining and fabrication to final testing, every component undergoes rigorous validation to ensure it meets the required specifications. By keeping all manufacturing processes under one roof, we can continuously monitor quality, ensuring that each product aligns with our high standards.

What types of equipment does South Shore Controls manufacture in-house?

We specialize in manufacturing a wide range of custom machinery, including control panels, integrated automation systems, and other specialized industrial equipment. Our in-house production services span everything from precision laser cutting and waterjet cutting to complete assembly and testing, allowing us to serve diverse industrial needs with efficiency and precision.

Choose South Shore Controls for In-House Manufacturing Services

When you choose South Shore Controls for in-house production, you’re opting for a solution that emphasizes customization, precision, and efficiency. By managing everything internally—from manufacturing design to testing—we ensure a faster, more cost-effective production process. Our team has years of experience serving industries with specialized needs, ensuring that your project receives the attention and expertise it deserves.

Contact South Shore Controls today to discuss how we can bring your project to life with precision and efficiency. Learn more about our services today!