Industrial Preventive Maintenance

Industrial Maintenance Services

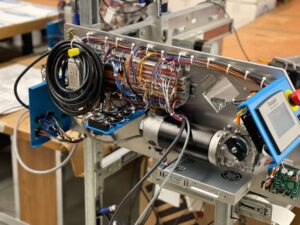

Keep your lines running with Industrial Preventive Maintenance from South Shore Controls. Our field service technicians deliver scheduled inspections, control panel and electrical checks, PLC/HMI and drive health reviews with software updates, network and safety verifications, and equipment optimization—identifying issues early to reduce unplanned downtime and extend asset life. We document findings and provide a practical, prioritized maintenance plan or service contract tailored to your plant and production schedule; when problems are discovered, we perform on‑site corrective repairs during planned windows to minimize disruption. Talk to an expert to set up a preventive maintenance program for your factory automation.

South Shore Controls provides comprehensive maintenance services for factory automation equipment, combining skilled technicians with a proactive approach to upkeep.

By entrusting preventative maintenance to South Shore Controls, manufacturers can proactively address potential issues, optimize their automation systems, and ensure a reliable and continuous production environment. The development of customized preventative maintenance programs further underscores South Shore Controls’ commitment to providing holistic solutions that meet the unique requirements of each manufacturing client.

- Scheduled Inspections: Routine inspections by experienced technicians to identify and address potential issues before they impact operations.

- Equipment Optimization: Fine-tuning and optimizing automation systems for peak performance, ensuring that all components work seamlessly together.

- Software Updates and Upgrades: Keeping automation software up-to-date to leverage the latest features, security patches, and improvements.

- Emergency Repairs: Swift response to unexpected issues, minimizing downtime and ensuring rapid resolution of problems.

- Custom Preventative Maintenance Programs: South Shore Controls collaborates with manufacturers to develop customized preventative maintenance programs tailored to the specific needs of their equipment and production processes.

South Shore Controls Provides On-Site Services for Factory Automation

As an automation systems integrator and specialty equipment manufacturer we understand the importance of after-sales support, equipment maintenance, integrating existing valuable manufacturing equipment with newer technologies to improve your manufacturing processes.

Our highly-skilled team of automation field service technicians have all the tools needed to support your manufacturing needs to improve your processes and minimize downtime.

- Repairs

- Evaluations

- Controls Support

- Installations

- Training

- Commissioning

- Preventative Maintenance

- Service Contracts

- Upgrades

- Systems Integrations

Project Gallery

Importance of Preventative Maintenance

Preventative maintenance is crucial for manufacturers relying on factory automation equipment as it ensures continuous and efficient operation while minimizing unexpected breakdowns and disruptions. South Shore Controls recognizes the significance of proactive maintenance and stands as a reliable partner for manufacturers seeking to safeguard their automation investments.

Importance of Preventative Maintenance:

- Minimizing Downtime: Scheduled maintenance helps identify and address potential issues before they escalate, reducing the risk of unexpected breakdowns and unplanned downtime.

- Extending Equipment Lifespan: Regular maintenance ensures that components are operating within optimal parameters, extending the lifespan of factory automation equipment and maximizing the return on investment.

- Enhancing Efficiency: Well-maintained equipment operates more efficiently, leading to improved productivity, reduced energy consumption, and higher overall operational efficiency.

- Cost Savings: Proactive maintenance is often more cost-effective than reactive repairs. It helps avoid expensive emergency repairs and minimizes the impact of major failures.

- Ensuring Safety and Compliance: Regular maintenance checks contribute to a safer working environment, addressing potential safety hazards and ensuring compliance with industry regulations.

By entrusting preventative maintenance to South Shore Controls, manufacturers can proactively address potential issues, optimize their automation systems, and ensure a reliable and continuous production environment. The development of customized preventative maintenance programs further underscores South Shore Controls’ commitment to providing holistic solutions that meet the unique requirements of each manufacturing client.

Discuss Your Project with Our Team Today

Contact our automation and controls experts to learn how we can help improve and automate your manufacturing processes.