Defense & Aerospace Automation Solutions

Aerospace Defense

South Shore Controls’ automation services hold immense value for the aerospace industry by seamlessly integrating advanced automation solutions into their manufacturing and operational processes. Here’s how their automation services can benefit the aerospace sector:

- Precision Manufacturing: In aerospace, precision is paramount. South Shore Controls’ automation expertise ensures precision manufacturing through the implementation of automated systems for machining, assembly, and quality control. This leads to consistently high-quality aerospace components and products.

- Efficient Production Workflows: Automation streamlines production workflows by incorporating robotic systems, automated conveyors, and material handling solutions. This efficiency not only accelerates production timelines but also reduces operational costs, contributing to overall competitiveness in the aerospace market.

- Quality Assurance: The aerospace industry demands rigorous quality standards. South Shore Controls’ automation solutions include advanced inspection and testing processes, enhancing quality assurance. Automated inspection systems provide accurate and reliable results, ensuring compliance with stringent aerospace regulations.

- Flexible Manufacturing Systems: The dynamic nature of aerospace manufacturing requires flexibility. South Shore Controls designs and implements flexible manufacturing systems that can adapt to changing production demands, enabling aerospace companies to respond swiftly to market shifts and new project requirements.

- Reduced Human Intervention: Automation minimizes the need for extensive manual labor in repetitive or hazardous tasks, improving overall safety and reducing the risk of human errors. This is particularly crucial in the aerospace industry, where precision and safety are paramount.

- Customized Solutions: South Shore Controls specializes in tailoring automation solutions to meet specific industry needs. In the aerospace sector, where each component may have unique manufacturing requirements, the ability to provide customized automation solutions is a valuable asset.

- Data Analytics and Connectivity: Automation systems provided by South Shore Controls often incorporate data analytics and connectivity features. This allows aerospace companies to gather valuable insights into production processes, monitor equipment performance, and implement predictive maintenance strategies to minimize downtime.

- Regulatory Compliance: The aerospace industry is subject to strict regulatory frameworks. South Shore Controls ensures that their automation solutions comply with industry standards and regulatory requirements, providing aerospace clients with peace of mind in terms of legal and safety obligations.

South Shore Controls’ automation services bring substantial value to the aerospace industry by enhancing precision, efficiency, and quality throughout the manufacturing and operational processes. Their expertise in crafting tailored solutions ensures that aerospace companies can navigate the complexities of their industry with cutting-edge automation technology.

DEFENSE & AEROSPACE AUTOMATION EXPERTISE

Aerospace and defense manufacturers require specialized automation solutions that address their unique needs and requirements. These manufacturers need automation solutions that are reliable, efficient and cost-effective. South Shore Controls can provide aerospace and defense manufacturers with the expertise and technologies required to achieve their automation goals.

Automation in defense manufacturing refers to the use of robotic systems and advanced software technologies to manufacture various military equipment and vehicles. Automation systems have revolutionized the way military equipment is manufactured, with the potential to create parts more quickly, accurately and efficiently than manual labor. Automation technologies such as robotics have transformed the manufacturing process, leading to more efficient, safe and cost-effective processes.

In addition, the use of automation has led to higher levels of quality control and reduced human error, ensuring that military and aerospace equipment and vehicles meet the highest safety standards.

Benefits Of Robotic Systems Integrators For Military Equipment & Vehicle Component Assembly

The use of robotic systems integrators in military equipment and vehicle component assembly has numerous benefits. Robotic systems integrators are experts in the design, integration and implementation of automation technologies in manufacturing processes. They work with manufacturers to develop customized solutions that address their unique needs and requirements.

One of the primary benefits of using robotic systems integrators in military equipment and vehicle component assembly is increased efficiency. Integrating automation technologies, such as robotics, can significantly increase manufacturing efficiency, reduce cycle times and improve throughput. In addition, automated systems can operate 24/7, leading to increased productivity and reduced manufacturing time.

Another significant benefit of using robotic systems integrators is improved quality control. Automated systems can provide consistent and accurate manufacturing processes, leading to higher quality and reduced defects. As an added benefit, defense and aerospace automation can reduce the risk of injury and human error, leading to a safer working environment.

Vacuum Calibration Tables

South Shore Controls provides an excellent system for the sizing of ridged polymer profiles. Our machine fits many applications such as door panels, window frames and fencing panels.

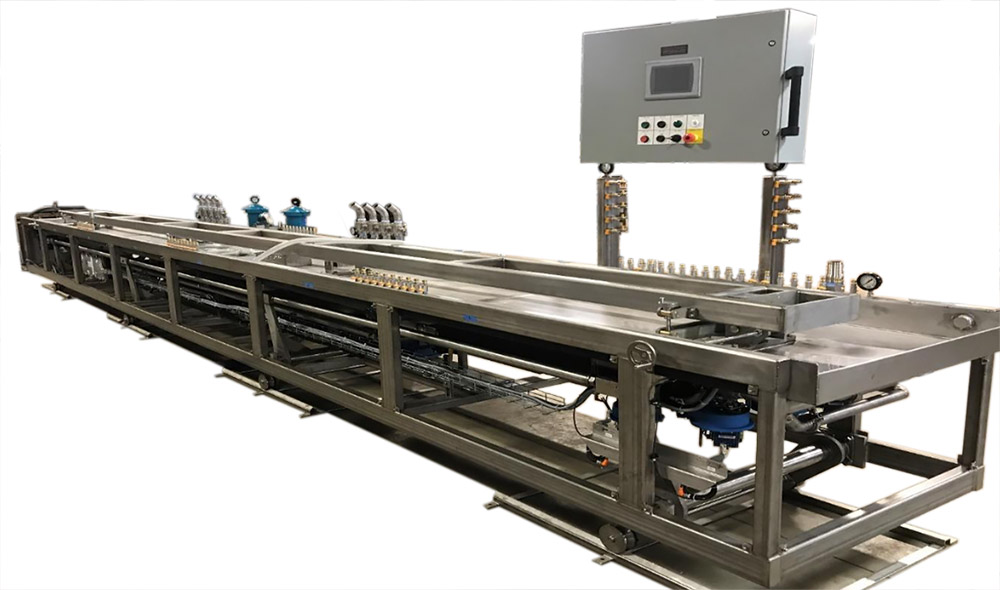

Industrial Parts Washing Machine

South Shore Controls provides an excellent system for the sizing of ridged polymer profiles. Our machine fits many applications such as door panels, window frames and fencing panels.

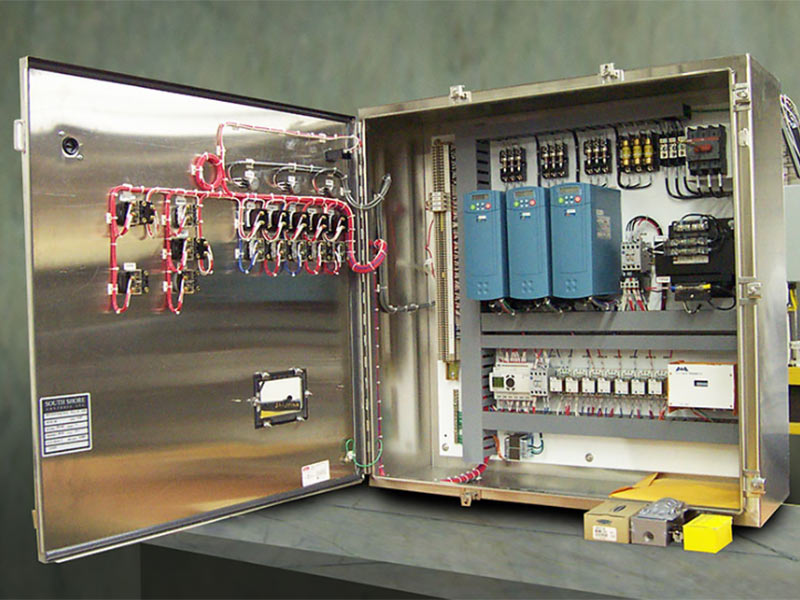

Industrial Control Panels & Control Cabinets

South Shore Controls provides an excellent system for the sizing of ridged polymer profiles. Our machine fits many applications such as door panels, window frames and fencing panels.

Frequently Asked Questions

What is system integration?

System integration is the process of introducing automated systems to help improve the functionality of your overall operation. Examples of automation system integrations include adding robotic pick and place systems or implementing position and presence monitoring.

Discuss Your Project with Our Team Today

Contact our automation and controls experts to learn how we can help improve and automate your manufacturing processes.