HMI Programming and Development

HMI programming and PLC programming are essential for seamless industrial automation in a manufacturing environment. At South Shore Controls, we specialize in designing and implementing comprehensive HMI development and programming solutions that allow operators to interact effectively with automated systems. Through precise PLC and HMI programming, we empower engineers and shop managers to achieve optimal control over their machinery, streamlining operations and enhancing productivity.

Our team develops HMI programming software that delivers intuitive, responsive interfaces, making it easy for operators to monitor, control, and troubleshoot equipment in real-time. Whether you’re exploring what HMI programming entails or looking for reliable PLC programming solutions, South Shore Controls provides the expertise to help you implement the best system for your facility.

Real-World Impact of HMI Software and PLC Systems

For manufacturers, HMI programming software and PLC systems are essential tools that translate the complex mechanics of automation into something manageable.

What is HMI programming?

HMI programming involves creating interfaces that allow operators to interact with industrial systems. Through these interfaces, users can monitor processes, input commands, and receive real-time feedback, enabling efficient control over automated machinery. With HMI technology, operators gain a visual interface, enabling them to track data, manage operations, and react swiftly to any issues. This kind of real-time control makes a world of difference on the production floor, where every second counts.

What is PLC programming?

PLC programming is the backbone of this setup. By handling everything from sequence control to machine responses, a PLC (Programmable Logic Controller) turns system designs into practical, day-to-day actions. It coordinates how and when machines operate, allowing for precision that simply isn’t achievable manually. When you think about what PLC programming does, it essentially automates decisions, so processes flow smoothly and efficiently, reducing the need for constant human intervention.

At South Shore Controls, our team takes PLC and HMI programming a step further. By customizing systems to each unique application, we ensure that both new and retrofitted setups achieve maximum efficiency. Whether your goal is to automate a single line or scale up with a fully integrated system, we have the expertise to build robust, reliable, and adaptable PLC and HMI programming solutions.

Tailored HMI Programming and PLC Programming Solutions for Every Industry

Every industry has unique needs, and South Shore Controls knows that HMI programming and PLC programming must adapt accordingly. From automotive to aerospace, the versatility of PLC and HMI programming makes it possible to design solutions that integrate smoothly with existing processes or lay the groundwork for new automated systems. Our team of specialists works closely with clients to understand their requirements, ensuring that each solution is a perfect fit.

In industries like pharmaceuticals or food and beverage, where precision is paramount, we configure HMI development to provide detailed process insights. This gives operators the power to make rapid adjustments and ensures that compliance standards are met without compromising efficiency. In heavy manufacturing sectors, our PLC programming solutions drive consistency and reliability, helping to reduce errors and improve safety.

By customizing PLC and HMI programming for different operational environments, South Shore Controls empowers businesses to tackle challenges head-on. Our focus is not just on automation but on creating systems that enhance productivity, safety, and quality across the board. Whatever your industry, we have the tools and expertise to deliver solutions that make a tangible difference.

Commitment to Quality and Expertise

Quality is at the core of everything we do. Reliable HMI programming and PLC programming are crucial for smooth operations, and our team goes the extra mile to ensure that each solution meets the highest industry standards. With a focus on precision and attention to detail, our programmers and engineers work to deliver systems that meet and exceed client expectations.

What sets us apart is our holistic approach to PLC and HMI programming. We don’t just install software and walk away. Instead, we provide full-service support, from initial concept and design through to installation, testing, and ongoing maintenance. Our end-to-end service model gives us the power to remain closely involved with our clients, addressing any concerns and fine-tuning systems as needed to keep their operations running smoothly.

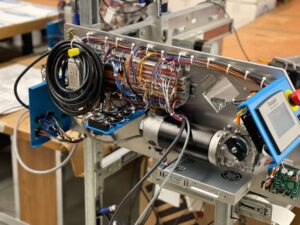

Project Gallery

South Shore Controls

Find out more about why South Shore Controls is your top choice for HMI programming and other industrial automation services.

Frequently Asked Questions About HMI Programming

If you have more questions about HMI programming, South Shore Controls is here to help. Below, we have answered some of the most common questions we hear.

Can HMI systems be integrated with existing automation setups?

Yes, HMI systems are designed to integrate seamlessly with existing PLCs and other automation equipment. Whether you’re upgrading an old system or adding new functionalities, HMIs can be programmed to communicate with different types of controllers, enhancing the flexibility and scalability of your automation setup.

How long does it take to develop and implement HMI and PLC programming?

The timeframe for developing and implementing HMI and PLC programming varies based on the project’s complexity, the scope of customization required, and the specific needs of the application. Simple systems may take a few weeks, while more complex integrations could span several months. South Shore Controls works closely with clients to establish realistic timelines and ensure efficient delivery.

What are the maintenance requirements for HMI and PLC systems?

Regular maintenance is key to ensuring the reliability and longevity of HMI and PLC systems. This typically includes software updates, hardware inspections, and routine checks for any potential issues. Preventative maintenance helps avoid unexpected downtime and keeps the system running optimally.

How does South Shore Controls ensure system security for HMI and PLC applications?

South Shore Controls prioritizes security by implementing robust measures such as data encryption, secure user authentication, and firewall protection. We also provide guidance on best practices for safeguarding control systems against cyber threats, ensuring that all HMI and PLC applications are secure and compliant with industry standards.

Improve Automation With HMI Programming & PLC Programming from South Shore Controls

South Shore Controls is here to provide industry-leading HMI programming and PLC programming solutions that transform your operations. With a commitment to quality and a focus on customized service, we help businesses like yours achieve efficiency and reliability. Contact South Shore Controls today to discuss your needs and discover how our expertise can enhance your automation strategy.