EV and Automotive Automation Solutions

The automotive industry is rapidly changing, including the rise of electric vehicles (EVs) and automotive automation. The integration of automation in the auto industry is becoming increasingly popular, and it is important for tier 2 and tier 3 automotive suppliers to understand its applications and benefits.

What Is Automation in the Automotive Industry for Tier 2 & Tier 3 Suppliers?

South Shore Controls is your go-to source for information on the latest trends in the automotive industry. We provide valuable insights into the world of EV and automotive automation solutions, helping suppliers stay ahead of the competition. Discover automotive manufacturing solutions from South Shore Controls today.

Automation has transformed the automotive industry, making it more efficient, cost-effective and sustainable. Tier 2 and tier 3 automotive suppliers play a critical role in this process, providing the parts, components and technologies that enable automotive manufacturers to automate their processes.

Tier 2 automotive suppliers are companies that supply parts or components directly to tier 1 suppliers, who then supply to automakers. Tier 3 automotive suppliers supply raw materials, components and services to tier 2 suppliers. These suppliers play a vital role in the automotive supply chain, and automation can help them improve their operations and stay competitive in the market.

From manufacturing automation to advanced safety systems, there are many applications of automotive automation for suppliers to explore.

Examples of Automation in Automotive Manufacturing Processes

In today’s highly competitive automotive market, manufacturers must embrace automation to remain competitive and meet consumer demand. Here are some examples of how automation is being used in automotive manufacturing processes:

- Robotic Assembly: Robots are being used to automate assembly processes, which improves efficiency and accuracy. Robotic arms can perform repetitive tasks with precision, such as welding, painting and attaching components.

- Machine Learning: Machine learning algorithms can optimize manufacturing processes. These algorithms can analyze data in real-time, identify trends and patterns and adjust manufacturing processes accordingly to improve efficiency.

- Autonomous Guided Vehicles (AGVs): AGVs transport materials and components throughout the manufacturing process. These vehicles are programmed to move independently, reducing the need for human intervention and improving efficiency.

- 3D Printing: 3D printing technology creates parts and components for vehicles. This technology allows manufacturers to create custom parts quickly and efficiently, reducing production times and costs.

- Predictive Maintenance: Predictive maintenance uses sensors to monitor equipment and identify potential maintenance issues before they occur. This technology can help reduce downtime and prevent equipment failures, improving efficiency and reducing costs.

- Artificial Intelligence (AI): AI is being used to optimize supply chain management and inventory control. By analyzing data, AI algorithms can help manufacturers identify trends and patterns in demand, reduce waste and improve efficiency.

- Augmented Reality (AR): AR technology is being used to improve worker training and efficiency. AR can provide workers with real-time guidance and instructions, reducing the time and cost associated with training.

Frequently Asked Questions About Automotive Automation

Want to learn more about automotive automation and how it can help your company? We have answered some common questions about automation in the automotive industry below.

What Do Robots Do in the Automotive Industry?

Robots play a crucial role in the automotive industry, performing various tasks that are repetitive, dangerous or require high precision. Some of the tasks that robots perform in the automotive industry include welding, painting, assembling and handling materials.

What Technology Is Used in Vehicular Automation?

Vehicular automation involves the use of a combination of technologies to enable vehicles to operate autonomously or semi-autonomously. Some of the key technologies used in vehicular automation include sensors, cameras, lidar, radar, GPS and artificial intelligence. These technologies work together to help vehicles navigate, detect obstacles and make decisions without human intervention.

What Are Advantages of Automation in the Automotive Industry?

The advantages of automation in the automotive industry are numerous. Some of the key advantages include:

Increased productivity

Improved quality and consistency

Reduced labor costs

Improved safety

Faster time-to-market.

Additionally, automation can also help automakers to optimize their supply chain and reduce waste, making the production process more sustainable.

Can IoT Monitoring Be Adapted to Any Industry?

Yes, IoT monitoring can be adapted to various industries, offering versatile solutions tailored to meet specific challenges and needs. From manufacturing, healthcare, and energy to logistics, IoT technology has proven to be transformative. It enables real-time monitoring, predictive maintenance, and operational optimization, making it possible to tailor IoT solutions to the unique requirements of different sectors. This adaptability is a testament to the versatility and potential of IoT monitoring to revolutionize industry operations across the board.

Automotive Automation Product Expertise

South Shore Controls provides valuable automotive automation product expertise, helping suppliers develop the knowledge and skills they need to succeed in the industry. Whether you’re looking to improve your manufacturing processes, develop advanced safety systems or integrate digital technologies into your products, we can provide the insights and guidance you need to succeed.

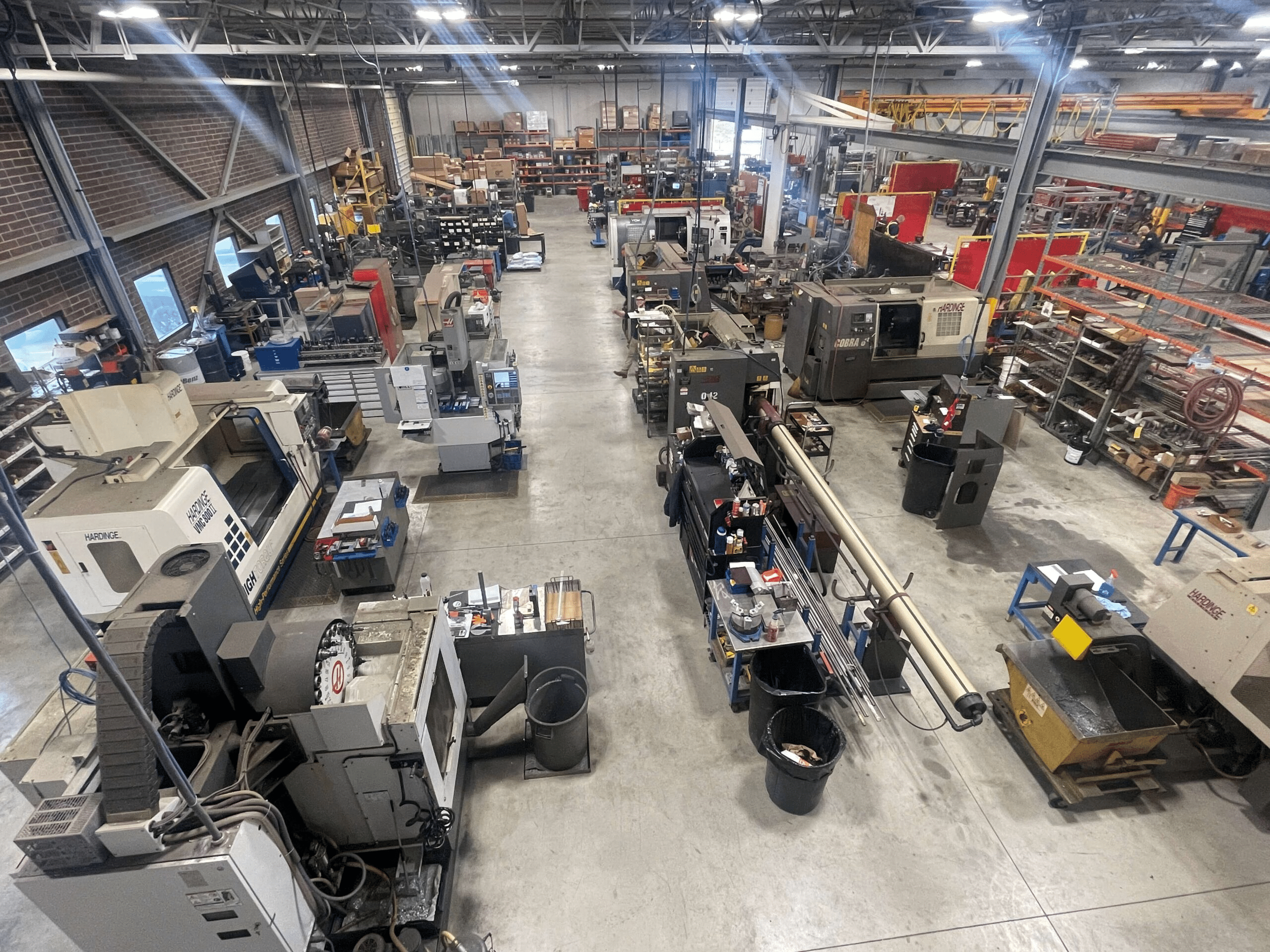

Automotive Automation Capabilities

We understand the challenges that automotive manufacturers face when it comes to improving efficiency and productivity while maintaining high levels of quality and safety. That’s why we offer a range of automotive automation capabilities to help our clients achieve their goals.

Our expertise in automotive automation covers a wide range of applications, including assembly, material handling, packaging, testing and more. We work closely with our clients to develop customized automation solutions that meet their specific needs and requirements.

One of our core strengths is our ability to integrate advanced technologies into our automotive automation systems. We have experience with a variety of cutting-edge technologies, including:

- Robotics

- Machine vision

- Artificial intelligence

- Internet of Things (IoT) sensors

By leveraging these technologies, we can design automation systems that are highly efficient, reliable and flexible.

Get Automotive Manufacturing Solutions for Tier 2 & 3 Automotive Suppliers

Our team of automation engineers has years of experience working in the automotive industry, which gives us a deep understanding of the unique challenges and requirements of automotive manufacturing. We are committed to delivering high-quality automotive automation solutions that help our clients improve their operations and stay ahead of the competition.

Whether you are looking to automate a single process or an entire production line, we have the capabilities and expertise to help you achieve your goals. We can design and build custom automation systems from scratch, or we can modify and upgrade your existing systems to improve their performance and capabilities.

Talk with an Automotive Automation Solutions Expert

Ready to take your automotive manufacturing to the next level? Explore the possibilities of automotive automation for companies just like yours with South Shore Controls. Our experts can help you design and implement customized solutions that improve productivity, quality and safety while reducing costs across a number of industries. Contact us today to learn more and get started.